Structure

- GY — Communication room (field) outdoor optical cable

- T — filled structure

- S — ISteel-polyethylene bonded magnetic protection

Structure

- GY — Communication room (field) outdoor optical cable

- T — filled structure

- A — Aluminum-polyethylene bonded sheath

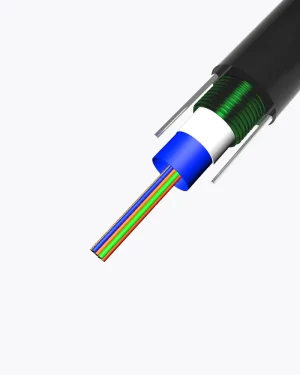

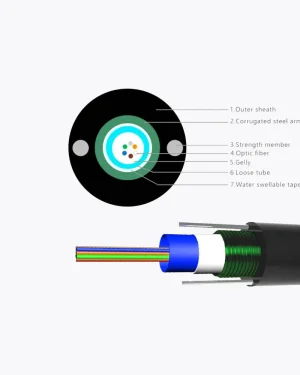

The mental strength member is made up of stranded steel wires as the supporting part are completed with a polyethylene(PE) sheath to be figure 8 structure. Corrugated steel tape armored and PE outer sheath providing crush resistance and gun shot resistance features. The steel-wire strength member as the central strength improves the tensile strength and it is surrounded by the loose tube and water blocking system. The impact structure ensures excellent mechanical and environmental performance.

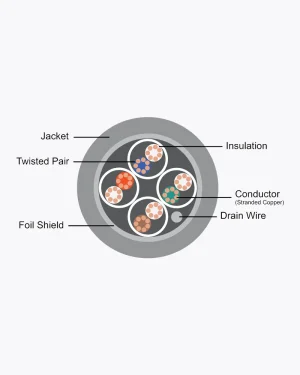

What is Differences between GYTS optical cable and GYTA optical cable?

GYTS cable is universal optical cable; it can be used in aerial, duct and direct-buried while GYTA can be used in aerial cable and duct cable not in direct-buried cable.The S in GYTS refers to steel strip which can sustain large pulling force, the A in GYTA refers to Aluminum strip which has better anti-rust and moisture resistance than steel strip, therefore, GYTA cable has longer service life when used in duct transmission. Choose GYTS cable when tensile strength is needed.

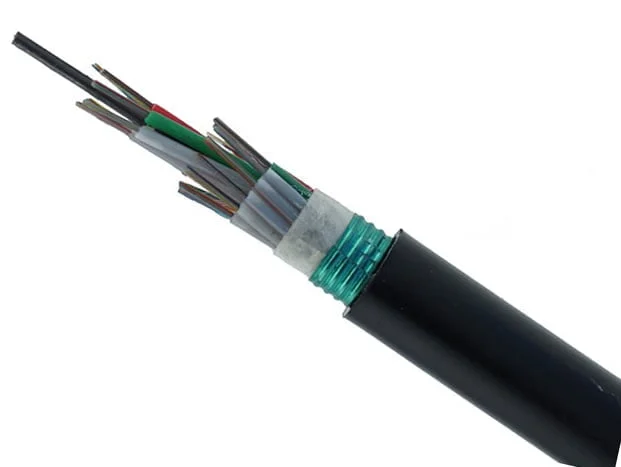

The Standard Loose Tube Light Armored Cable, or GYTS cable for short, is a type of outdoor fiber optic cable designed for aerial, duct, and direct buried applications.

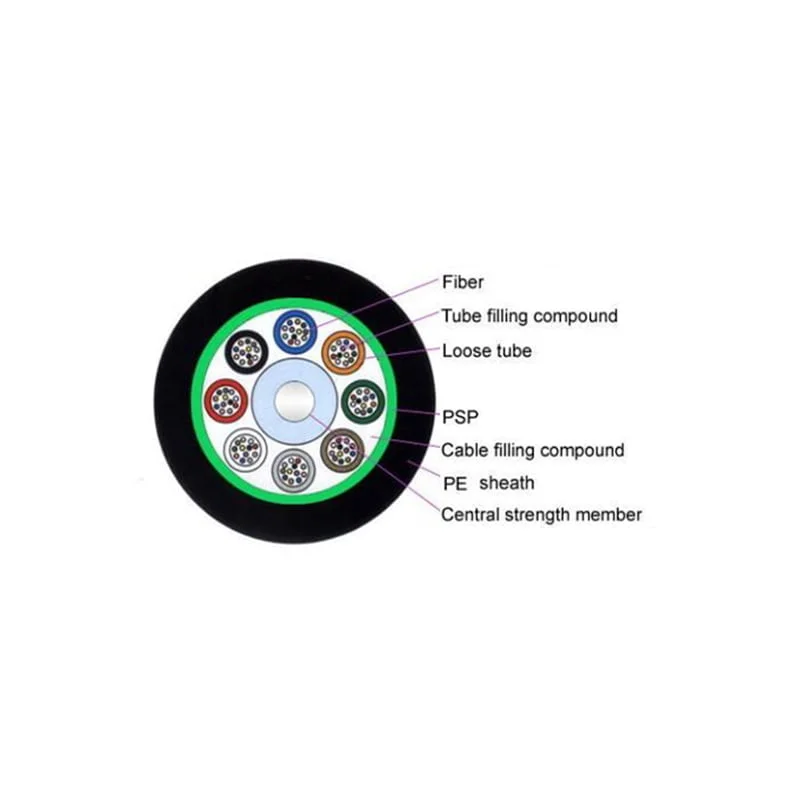

Here’s a breakdown of its construction:

- Loose Tubes: GYTS cables contain multiple loose tubes, typically made of a high modulus plastic that is resistant to hydrolysis. Each tube contains a few color-coded optical fibers and is filled with a gel that protects the fibers from moisture and other environmental factors.

- Central Strength Member: A central strength member, usually a steel wire or fiberglass rod, runs through the center of the cable and provides tensile strength and stability.

- Filling Compound: The spaces between the loose tubes and the central strength member are filled with a water-resistant filling compound that provides additional protection from water ingress.

- Corrugated Steel Tape Armor: A layer of corrugated steel tape is applied longitudinally over the cable core. This armoring provides excellent crush resistance and protects the cable from rodent damage.

- Outer Sheath: The final layer is a black polyethylene (PE) sheath that protects the cable from ultraviolet radiation, abrasion, and other environmental hazards.

Here are some of the key features and benefits of GYTS cables:

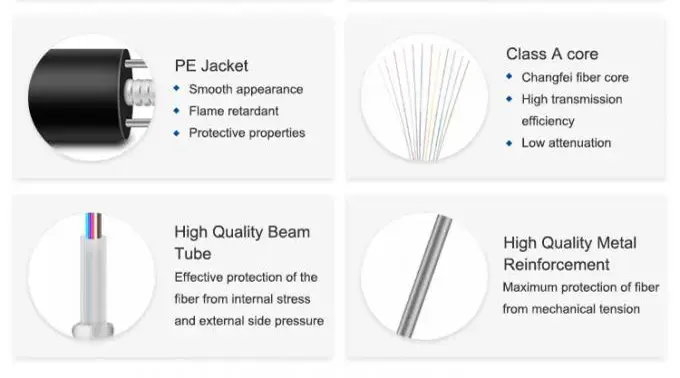

- Excellent mechanical and temperature performance: Due to the loose tube design and controlled fiber excess length, GYTS cables can withstand a wide range of temperatures and harsh environments.

- Superior water blocking: The combination of water-resistant filling compound, central strength member, and Polyethylene sheath ensures excellent water blocking performance.

- Crush resistance and flexibility: The corrugated steel tape armoring and loose tube design make GYTS cables resistant to crushing and provide good flexibility for easy installation.

- Ultraviolet protection: The black PE outer sheath protects the cable from the harmful effects of ultraviolet radiation.

- Wide range of fiber counts: GYTS cables are available in a variety of fiber counts, typically from 2 to 288 fibers, to accommodate different applications.

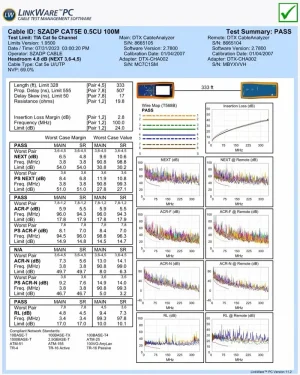

- Standards compliance: GYTS cables typically comply with international standards such as IEC 60794-1 and YD/T 901-2001.

Overall, GYTS cables are a versatile and reliable choice for a variety of outdoor fiber optic applications. They offer excellent performance, durability, and water resistance, making them ideal for data centers, enterprise networks, and telecommunication applications.

Additional Options

We offer a range of cables including the GYTA, GYXTW, GYTA53, GJFJV, and ADSS models. These cables are suitable for both indoor and outdoor use, providing flexibility based on specific needs and installation conditions. Notably, these cables are particularly effective in environments where high levels of moisture resistance and rodent protection are crucial. Each type is designed to meet different operational requirements, ensuring reliable performance across various applications.

Benefits of the GYTS Cable

GYTS cable stands out due to its hydrolysis resistance and high strength, making it particularly suitable for demanding environments. The combination of durable materials and advanced design features ensures that the cable maintains performance and reliability even in harsh conditions. Its robust construction not only protects the fibers from physical damage but also provides excellent moisture and rodent resistance. As a result, the GYTS cable is a dependable solution for various networking needs, offering both longevity and consistent performance in diverse applications.