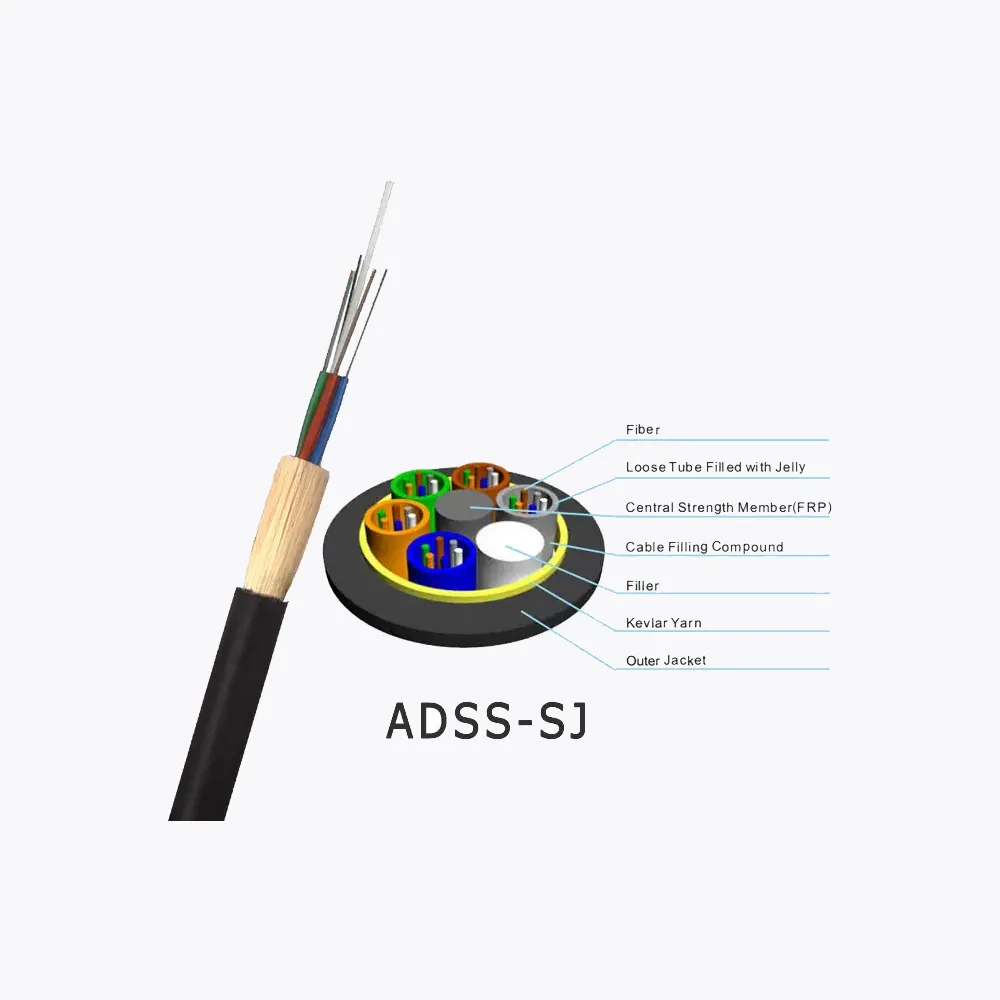

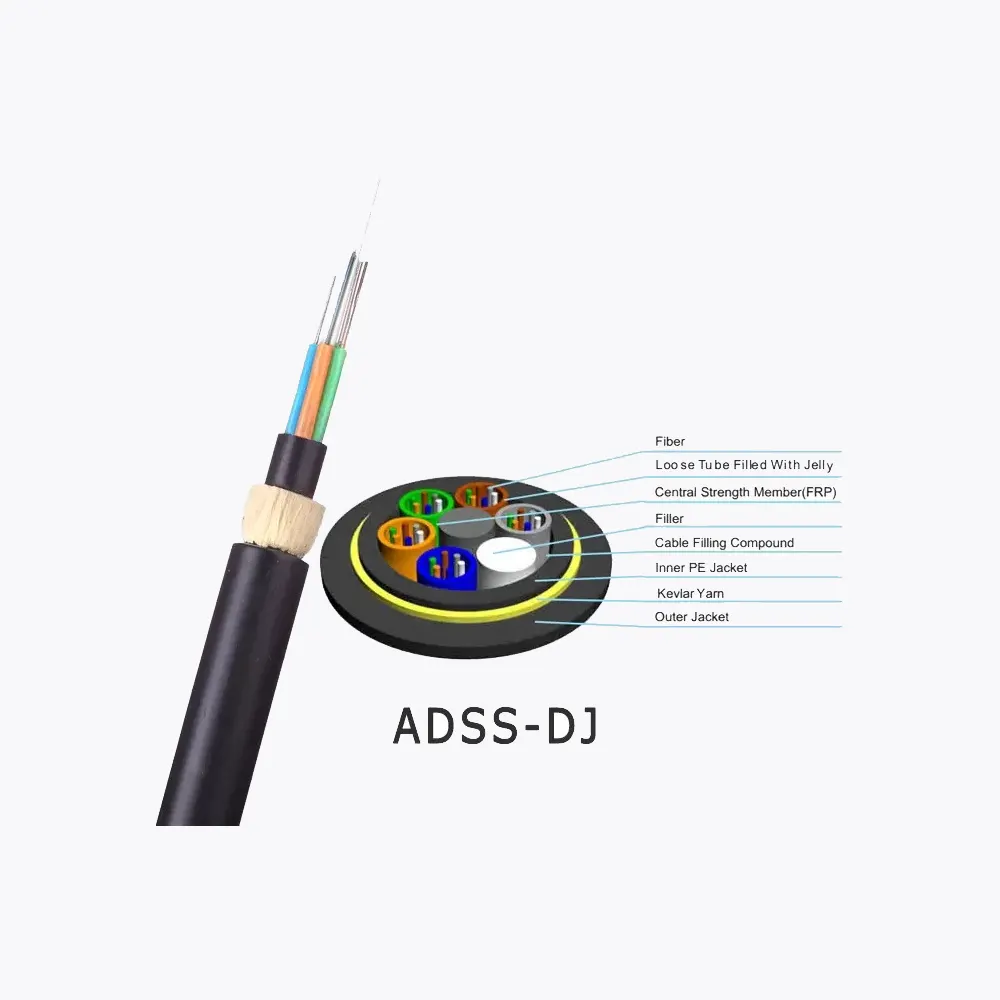

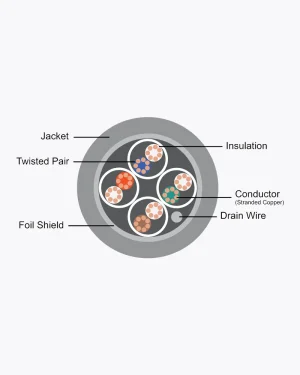

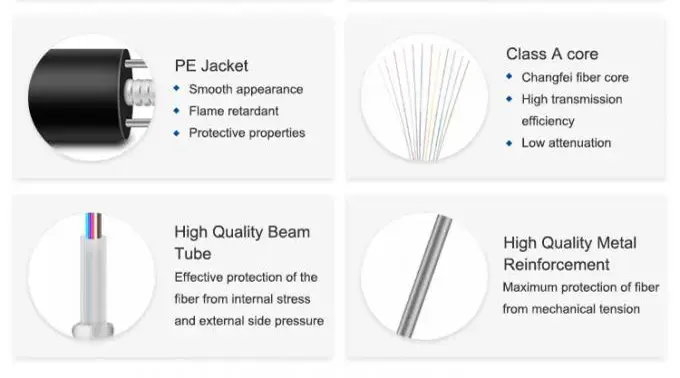

After the cable core is filled with filling compound. it is covered with thin PE (polyethylene) inner sheath. After stranded layer of aramid yarns are applied over the inner sheath as strength member, the cable is completed with PE or AT (anti-tracking) outer sheath.

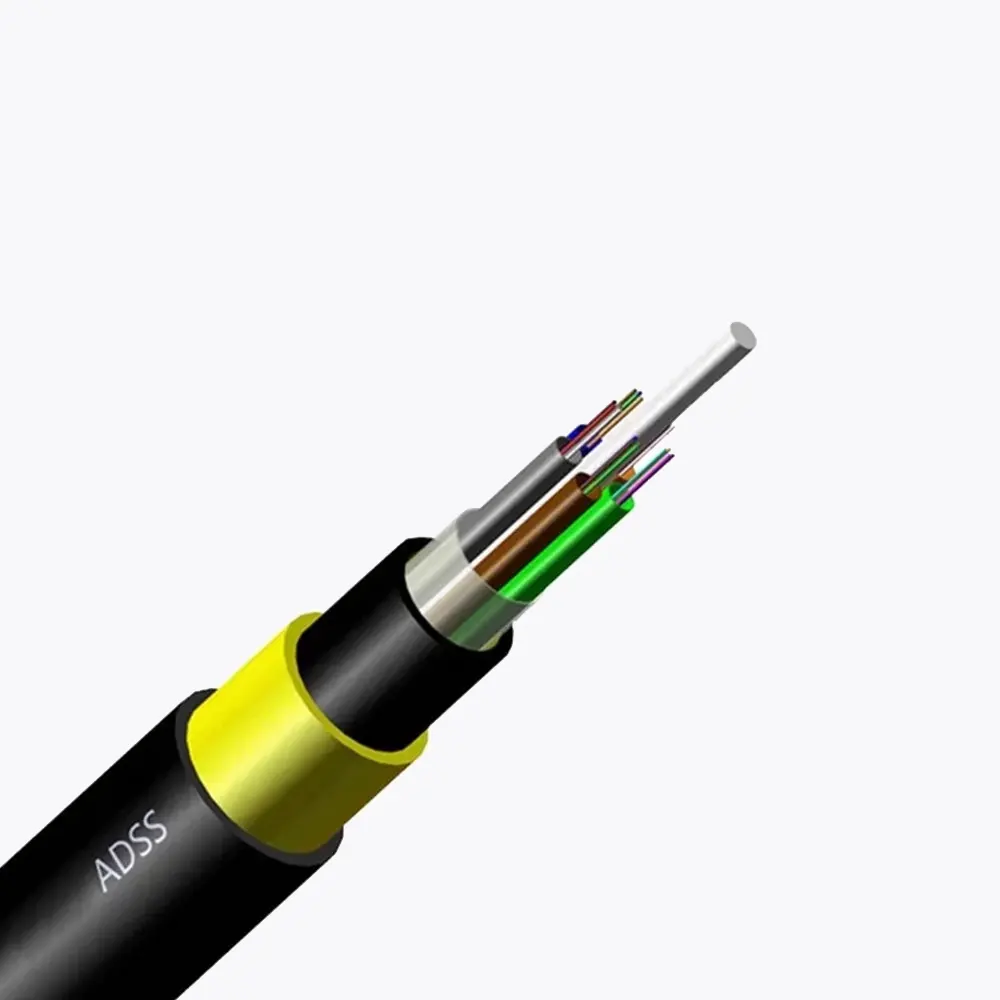

AFL-ADSS® (All-Dielectric Self-Supporting) fiber optic cable is designed for outside plant aerial transmission and distribution environments. As its name indicates, there are no metallic components and the cable does not require a support or messenger wire. These attributes allow the cable to be installed live-line and in the power space of distribution lines.

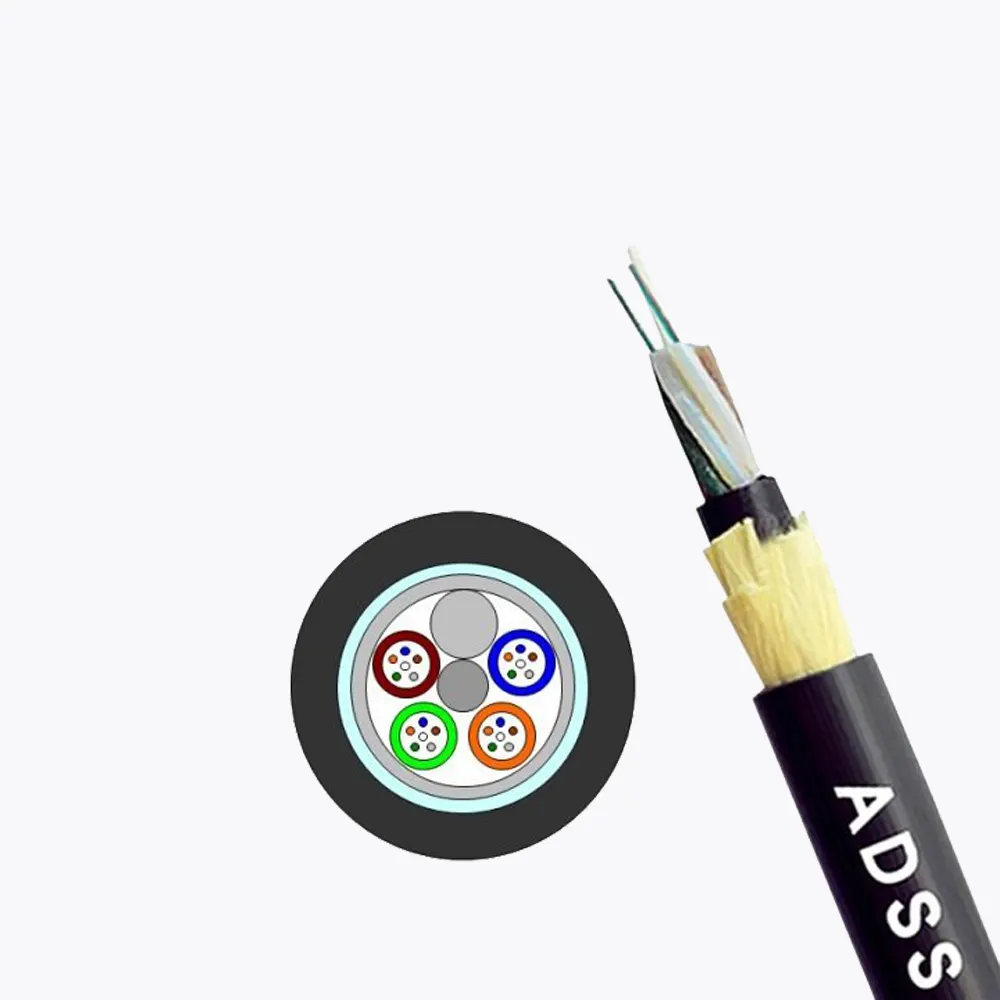

ADSS Cable is loose tube standard. Fibers, 250 µ m. are positioned into a loose tube made or high modulus plastics. The rubes are filled with a water-resistant lilting compound. The tubes (and fillers) arc stranded around a FRP (Fiber Reinforced Plastic) as a non-metallic central strength member Into a compact and circular cable core . After the cable core is filled with tilling compound.

- Up to 432 fibers in cable

– Gel-Free Buffer Tube options available – up to 216 fibers - Designs capable of span lengths up to 3500 ft.

- Double jacket designs provide additional protection to the fibers for longer span lengths and higher strength requirements

- Track-resistant outer jacket available for high voltage transmission lines for space potential values up to 25 kV

- Gel-filled tubes are reverse-oscillated (SZ stranded) to allow slack for mid-span access

ADSS Completely metal-free design with fiber counts from 12 to 288 fibers, suitable for deployment near high-voltage power lines in long spans. These cables can be installed in short spans between aerial poles without a separate messenger upon which to attach the optical cable. Also available in mid and long-length spans.

ADSS are All-Dielectric self supporting cable and single jacket designed for aerial installation. The optical fiber cable(ADSS) design provides no supporting part or messenger wire required. JIANYE provides for hardware part for installation with ADSS cable supporting on the pole. The cable inside multi-loose tube filled with a water resistant filling compound or design for waterblocked with water blocking material in side cable. The cable high tensile by aramid yarns and FRP strength member rod inside. Outer sheath made from HDPE.

Application of ADSS Cable

● Electric utility transmission and distribution power lines – Typically framed under conductors

● Enterprise OSP networks

● Fiber-to-the-X networks

● Aerial networking system